About Metalcutting Specialist Group, Ltd:

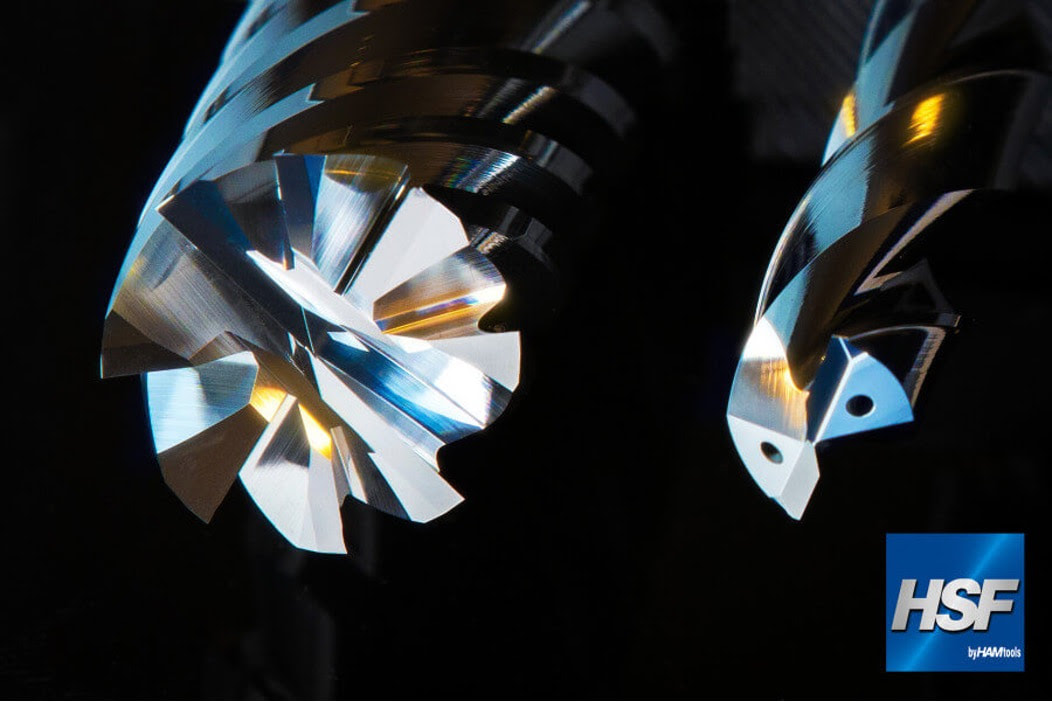

We present our manufacturing customers with tooling and workholding solutions that level the labor skills gaps, presenting maximum tool life, finishes and tolerances while applying efficiency to job setups that give ROI of 30 to 50 percent machine utilization improvements.

Factory Representation Leading with Knowledge, Integrity, and Service.

Our emphasis is cutting, holding, and cooling. This targeted focus encourages us to seek out innovative technologies for process improvement for further machine optimization.

Click here to find a representative in your area.

We present our manufacturing customers with tooling and workholding solutions that level the labor skills gaps, presenting maximum tool life, finishes and tolerances while applying efficiency to job setups that give ROI of 30 to 50 percent machine utilization improvements.

Factory Representation Leading with Knowledge, Integrity, and Service.

Our emphasis is cutting, holding, and cooling. This targeted focus encourages us to seek out innovative technologies for process improvement for further machine optimization.

Click here to find a representative in your area.

RSS Feed

RSS Feed